|

Koten Machinery Industry Co.,Ltd.

|

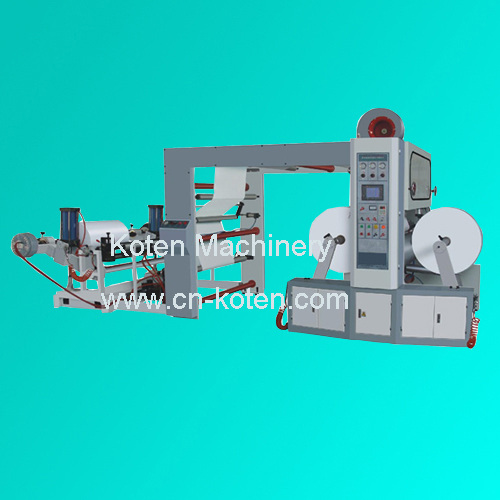

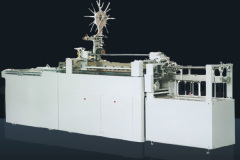

Slitting Rewinding Machine (Koten-BFQ Series)

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Slitting Rewinding Machine

Usage:

Thismachine is used for slitting and rewinding various rol-materials such as paper, cloth, PVC, PET and paper-plastic, material, etc.

Thismachine is used for slitting and rewinding various rol-materials such as paper, cloth, PVC, PET and paper-plastic, material, etc.

Function.

1This machine is in frame style structure with good stability. Specially suitable for slitting and rewinding large rolling material, such as paper, paperplastic laminating material, ect...

2It adopts imported pneumatic round cutter with high precision slitting and can be adjusted freely.

3It adopts surface rewinding style, diameter of rewinding if big and smooth.

4Rewinding mechanical axes core is in moving style, easy for rewinding the bigger and heavier rolling materials.

5Rewinding arm is quipped with full automatic invariable liquid pressure control system and pressure detector, as a result, the pressure will be more stability, and both inner and outer hardness of rewinding will be more symmetrical, excessive tension can be avoided.

6It adopts photoelectric automatic error correction adjustment system for rewinding, anomalistic materials will be easy slitted.

7It adopts automatic tension control system for unwinding and rewinding, easy controlling the tension of rewinding when the process of slitting, tension is with digital indication.

8Equipped with waste material automatic output device.

9This machine has the functions of the frequency converter timing, microcomputer control,

Photoelectric error corrrction device, automatic metering, stopping working with alarm, tension with digital indication, etc.

10 Automatic material inputting with liquid press.

1This machine is in frame style structure with good stability. Specially suitable for slitting and rewinding large rolling material, such as paper, paperplastic laminating material, ect...

2It adopts imported pneumatic round cutter with high precision slitting and can be adjusted freely.

3It adopts surface rewinding style, diameter of rewinding if big and smooth.

4Rewinding mechanical axes core is in moving style, easy for rewinding the bigger and heavier rolling materials.

5Rewinding arm is quipped with full automatic invariable liquid pressure control system and pressure detector, as a result, the pressure will be more stability, and both inner and outer hardness of rewinding will be more symmetrical, excessive tension can be avoided.

6It adopts photoelectric automatic error correction adjustment system for rewinding, anomalistic materials will be easy slitted.

7It adopts automatic tension control system for unwinding and rewinding, easy controlling the tension of rewinding when the process of slitting, tension is with digital indication.

8Equipped with waste material automatic output device.

9This machine has the functions of the frequency converter timing, microcomputer control,

Photoelectric error corrrction device, automatic metering, stopping working with alarm, tension with digital indication, etc.

10 Automatic material inputting with liquid press.

| Model | BFQ-1100 | BFQ-1300 | BFQ-1500 | BFQ-1800 |

| Max.unwinding width | 1100 mm | 1300 mm | 1500 mm | 1800 mm |

| Max.unwinding diameter | 1500 mm | |||

| Material suitable | 50gsm-400gsm(according to different materials) | |||

| Max.rewinding diameter | 800 mm | 1000 mm | 1200 mm | 1200 mm |

| Min.rewinding width | 50 mm(according to different materials) | |||

| Core diameter | 3 or 6 inches(or according to the users'request) | |||

| Max.Machine speed | 250 m/min | |||

Related Search

Slitting Rewinding Machine

Slitting And Rewinding Machine

Vertical Slitting Rewinding Machine

Rewinding Machine

Slitting Machine

Automatic Rewinding Machine

More>>